G90 and G91 GCodes Absolute and Incremental

Although G-Code is the standard language for most 3D printers, some machines may use different file formats or commands.. While G90 and G91 control the positioning mode for the X, Y, and Z axes, you can also use M82 or M83 to set your extruder (E-axis) to absolute or relative positioning. Arguments: None. Example usage: G90 ; use absolute.

G90 and G91 GCodes Absolute and Incremental

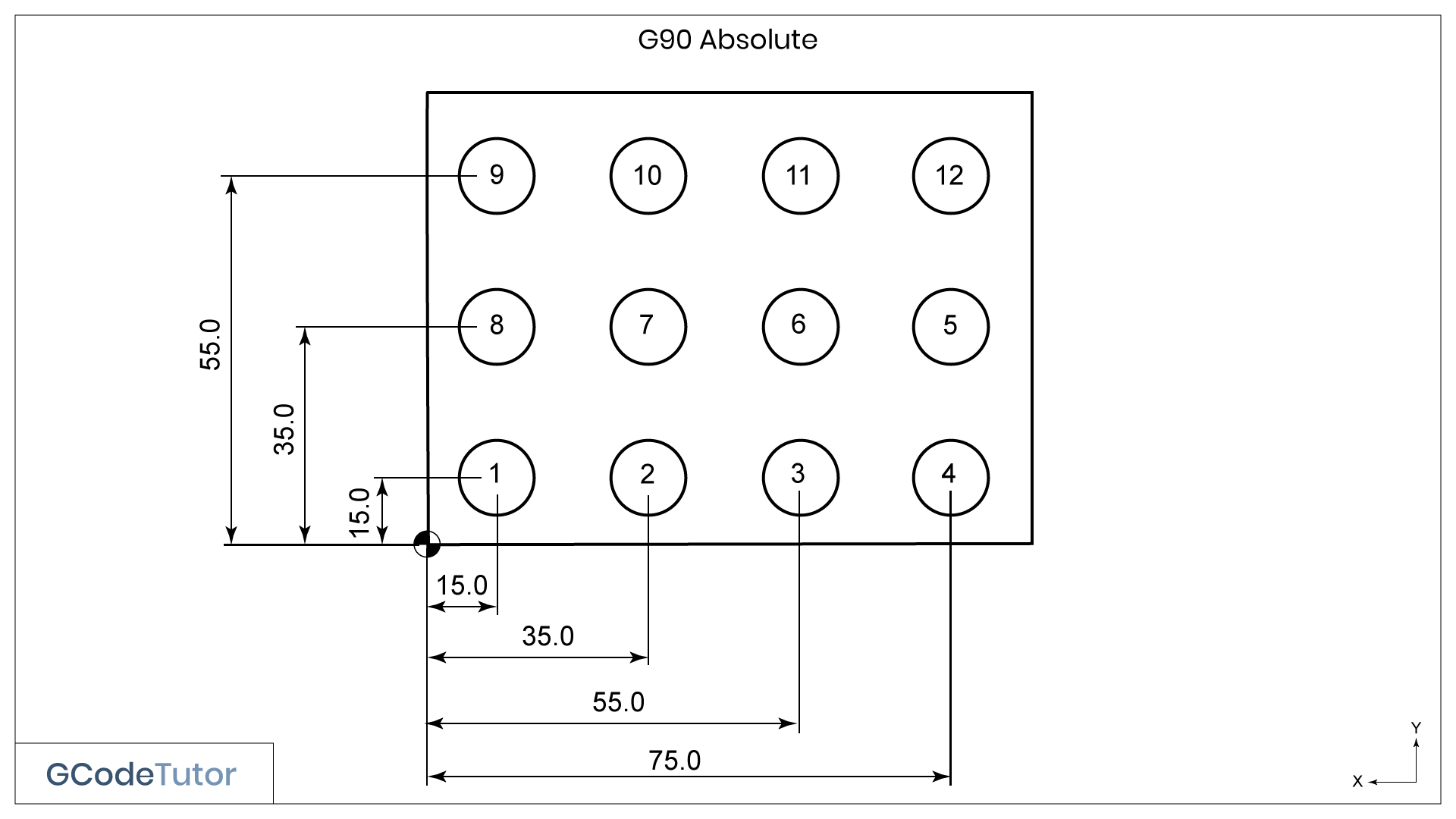

These G codes change the way the axis commands are interpreted. Axes commands following a G90 will move the axes to the machine coordinate. Axes commands following a G91 will move the axis that distance from the current point. G91 is not compatible with G143 (5-Axis Tool Length Compensation).

fiesta atravesar clon g90 g91 g code Posicionar Ídolo cuello

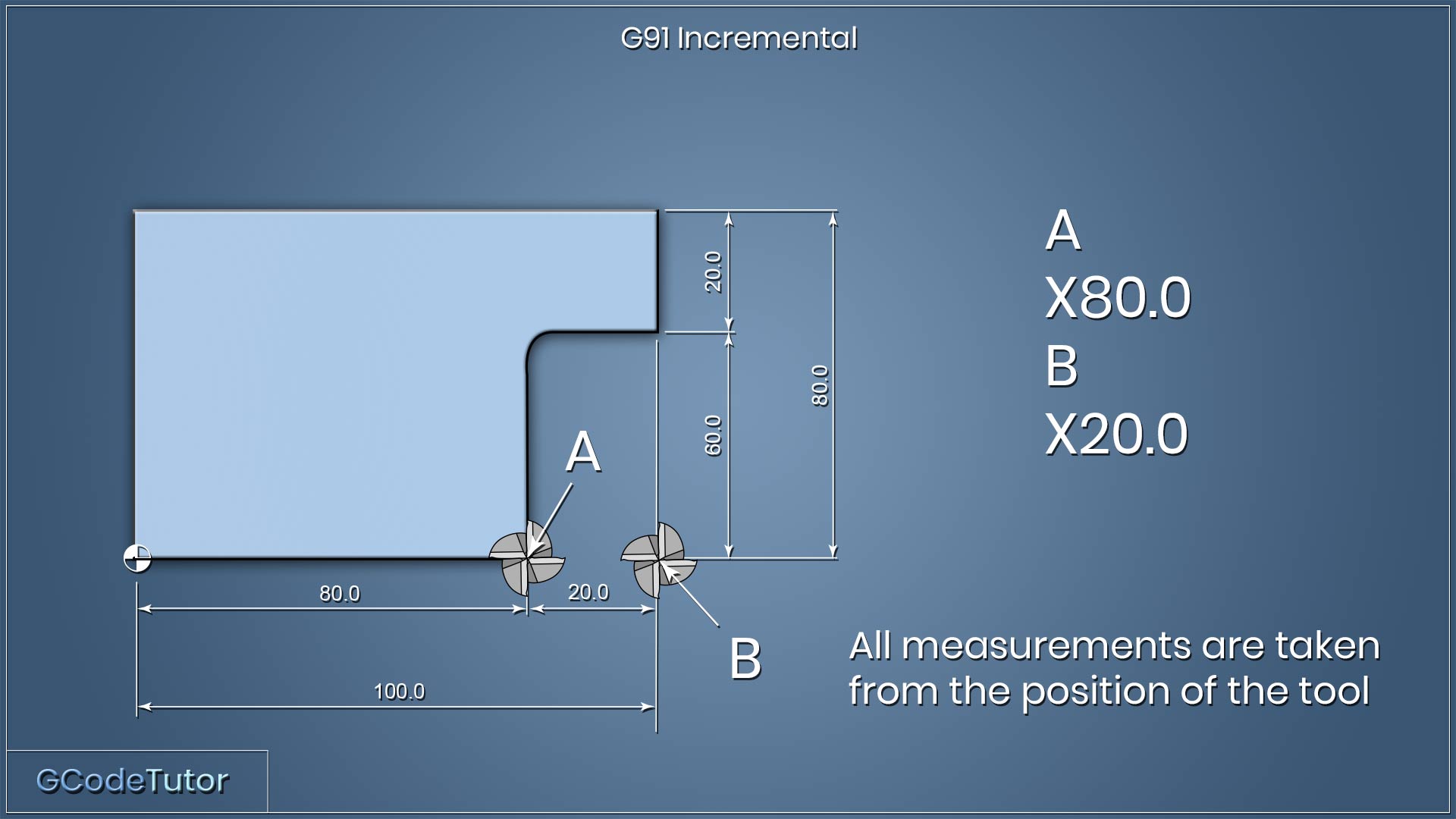

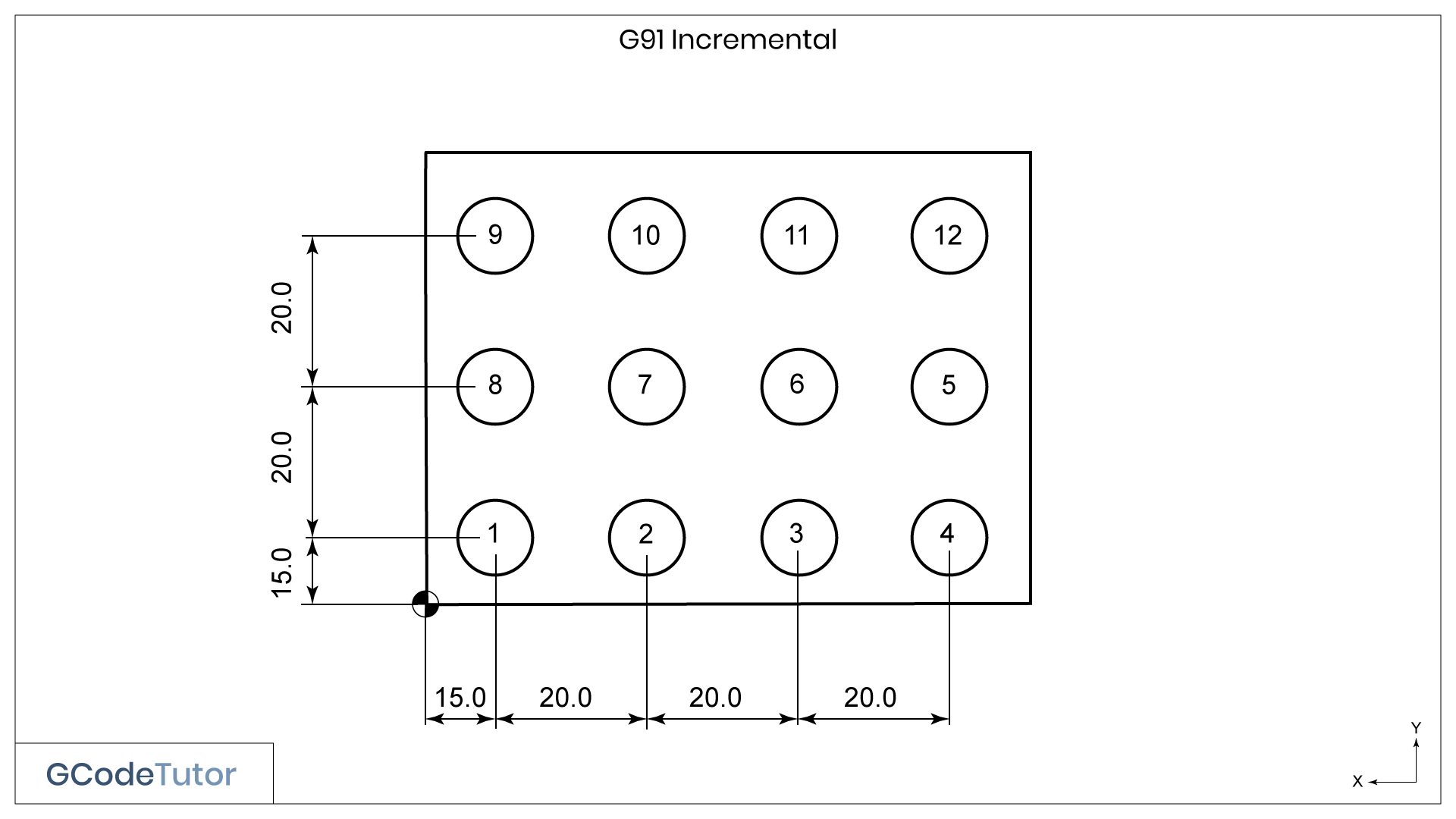

G91 is a G-code command used in CNC machining. It is used to switch the machine's coordinate system to incremental mode. In incremental mode, the machine moves in relation to its current position, rather than to an absolute position. This can be useful for certain machining operations, such as drilling a series of holes at precise intervals.

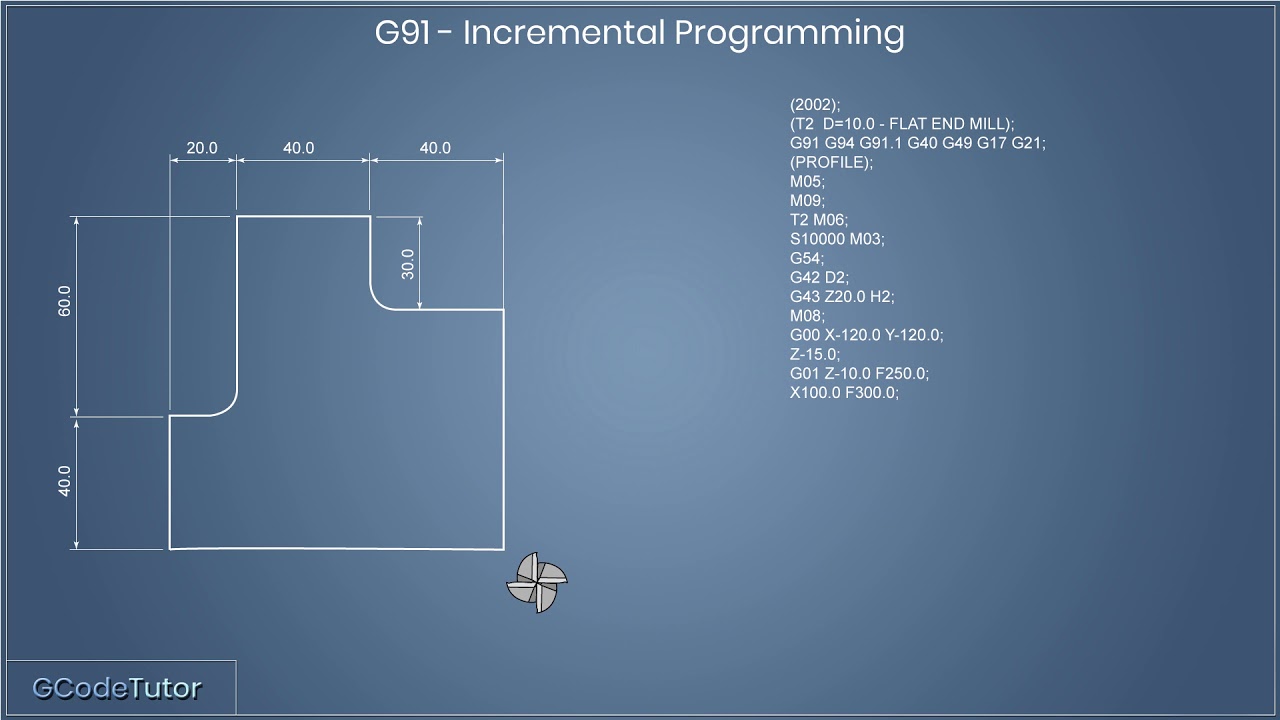

CNC Router Programming using GCode and the incremental G91 system. YouTube

G91 is a G-code used to set the distance mode to incremental. It means that all coordinates are given in reference to the machine's current position. With the G91 mode, the machine will move to a position relative to its current position, rather than to a specific absolute coordinate. For example, if a G-code program has the command G91 G0 X10.

Gcode数控机床编程教程【CNC】 BimAnt

The G81 Example 1 demonstrates how a canned cycle could be used to produce 8 holes with ten lines of G code within the canned cycle mode. The program below will produce the same set of 8 holes using five lines for the canned cycle.. G91 - incremental distance mode In incremental distance mode, axis numbers usually represent increments from.

G90 And G91 GCode Commands How To Use

G91: Relative Positioning G92: Set Position G425: Backlash Calibration M0-M1: Unconditional stop M3: Spindle CW / Laser On M4: Spindle CCW / Laser On M5: Spindle / Laser Off M7-M9: Coolant Controls M10-M11: Vacuum / Blower Control M16: Expected Printer Check M17: Enable Steppers M18, M84: Disable steppers M20: List SD Card M21: Init SD card

G90 and G91 GCodes Absolute and Incremental

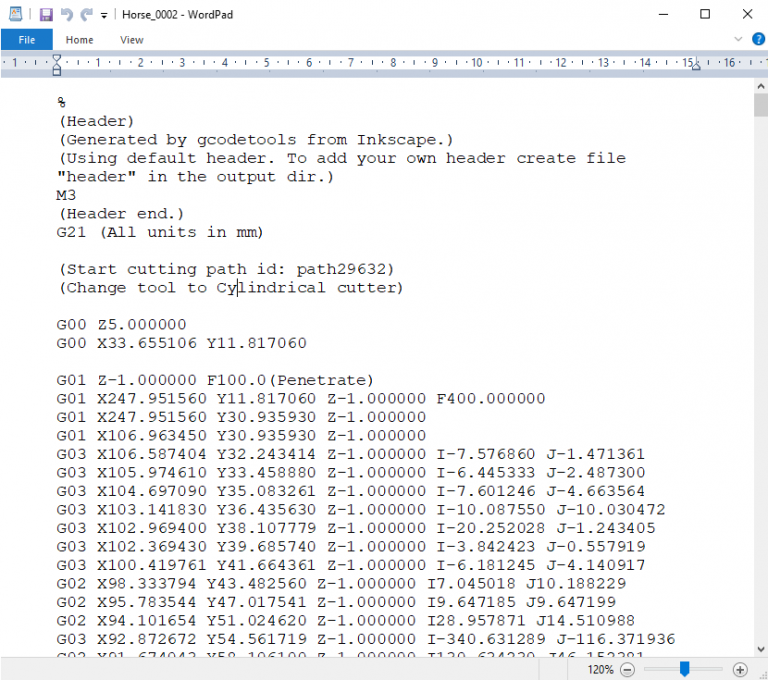

G code units will either be in inches or millimeters. The header should have a G20 if the units are in inches and a G21 if the units are in millimeters. There's never a good reason to mix units within the same program. The header should also declare whether the coordinates in the file are absolute (G90) or incremental (G91).

Quick Guide to the G91 CNC G Code [Tips and Tricks]

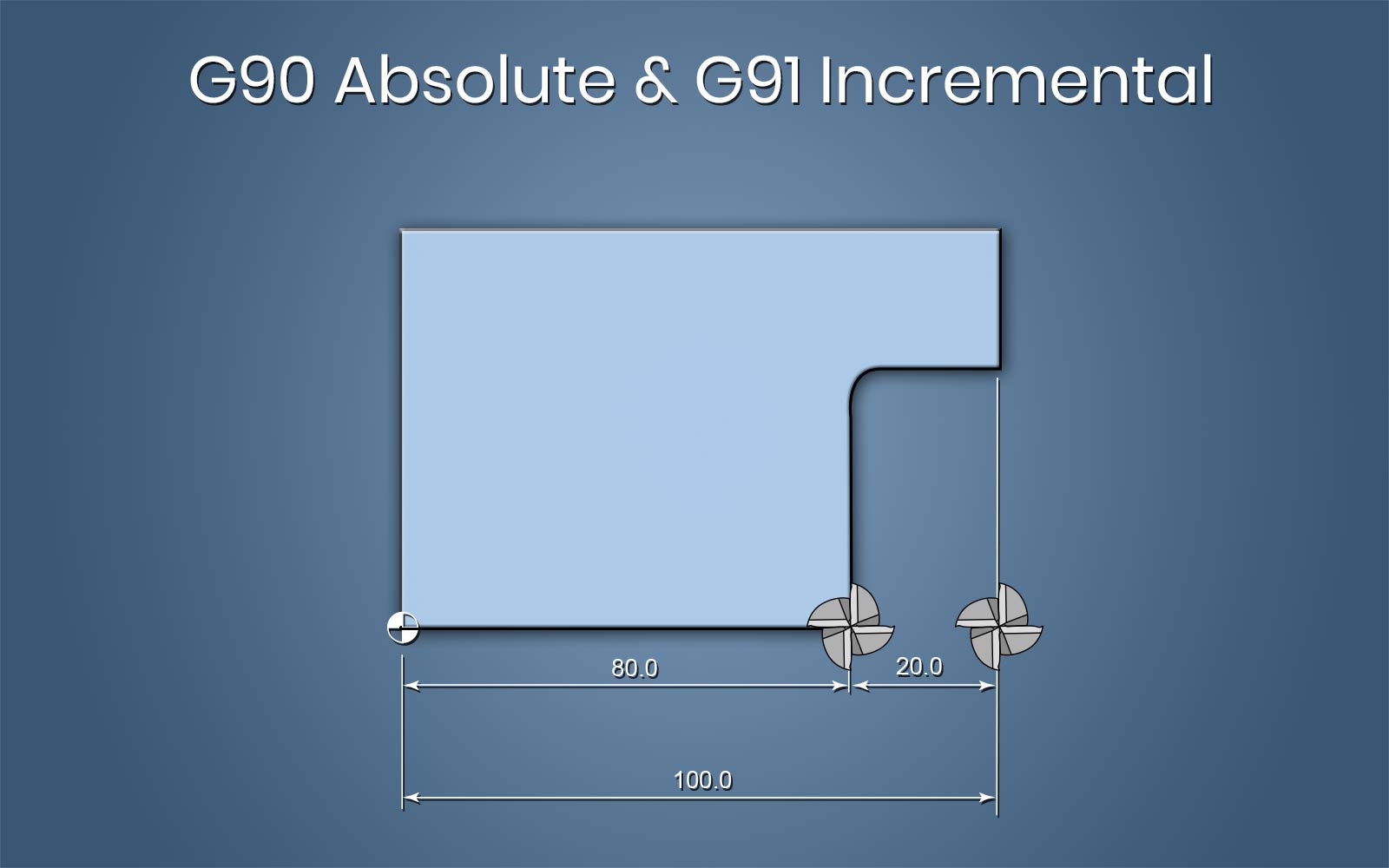

Also known as absolute (G90) or incremental (G91) programming. These G-Codes tell the machine controls how to read the measurements. Below we take a look at how each one works G90 Absolute positioning The G Code G90 is used to define the absolute positioning system.

G90 And G91 GCode Commands How To Use

With incremental positioning (G91), the machine will interpret all locations as relative to the current location. In other words, once the machine moves to a new location, that location becomes the new zero. G90 and G91 code are both modal. Modal commands stay active until it is either canceled or changed. For G90 and G91, there is no cancel code.

G90 And G91 GCode Commands How To Use

These are commands that one may enter into the OctoPrint terminal tab. G-Code commands Klipper supports the following standard G-Code commands: Move (G0 or G1): G1 [X

G90 And G91 GCode Commands How To Use

What does a G91 code do? A G91 code sets the CNC to incremental positioning mode. This means that the CNC will interpret all location values as relative to the position of the machine before making the move. The zero location of the machine will move each time the machine moves.

G90 и G91 GCode абсолютные и относительные системы координат

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. This means that they set modes or prepare the machine for various actions. We have put together a complete list of G codes for your reference. Not all codes are used often.

G90 and G91 G Codes Cnc programming, Cnc, Coding

The G81 Example 1 demonstrates how a canned cycle could be used to produce 8 holes with ten lines of G-code within the canned cycle mode. The program below will produce the same set of 8 holes using five lines for the canned cycle.. (G91) and OLD_Z retract mode (G98). It also calls for the G81 drilling cycle to be repeated three times. The X.

CNC ABSOLUTE & INCREMENTAL DIMENSIONING // CNC CODE EXPLAINED G90,G91 //G90 VS G91// CNC CODES G

Once you call a G90 mode, this mode will stay active until you call a G91 command. The G90 command tells the machine that the G code positions that we send in our program will be absolute values.

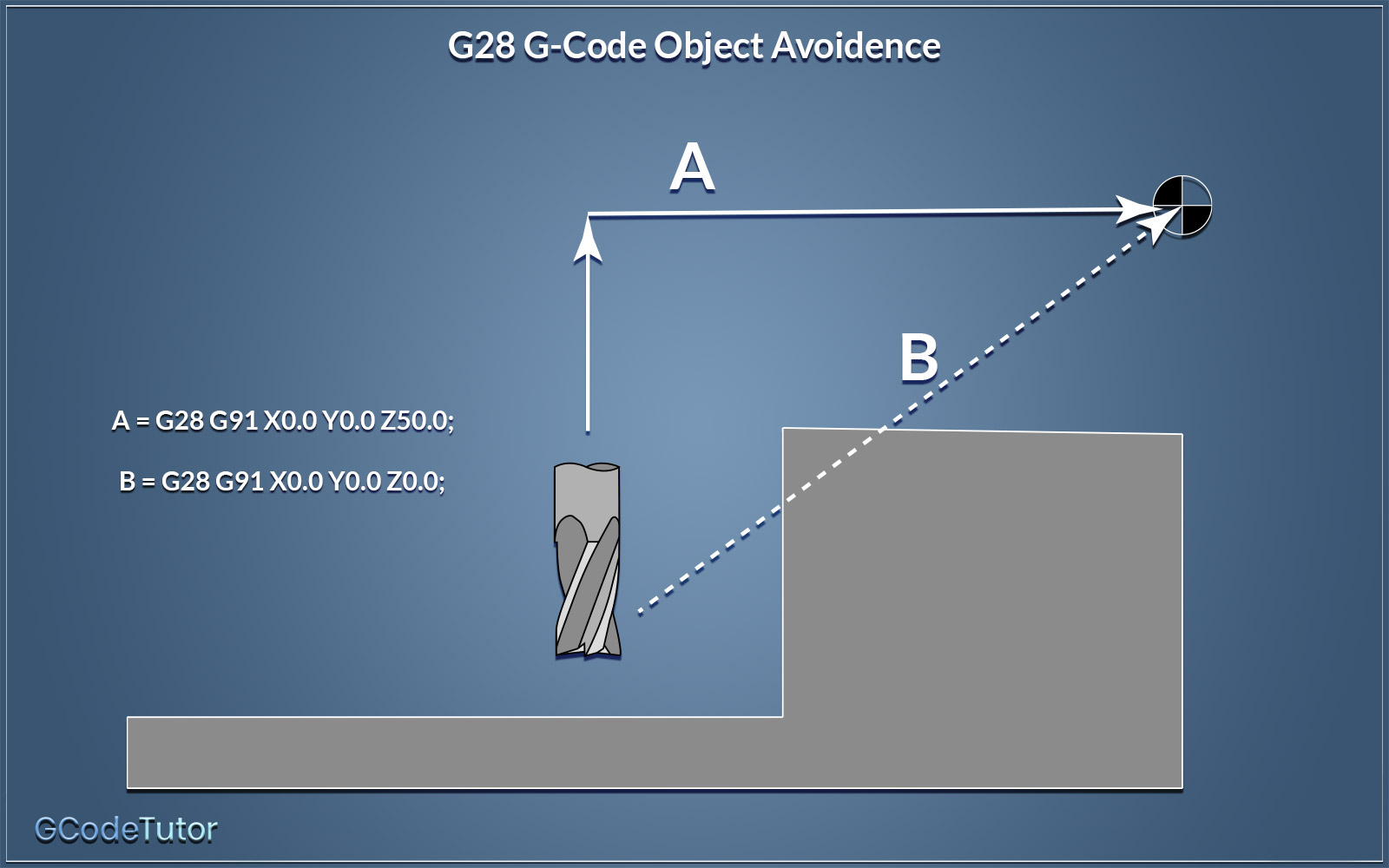

G28 GCode the go home command for Gcode

In this G-code tutorial, we go back to basics on a topic that often confuses programmers starting out with G-code programming: absolute vs incremental positi.

G90 and G91 GCodes Absolute and Incremental

G-code has two positioning modes: G91 is incremental, while G90 is absolute. Learn the important difference between G91 and G90 G-code!